Polyethylene, abbreviated as PE, is one of the most widely used types of plastic. It can be found in everything from grocery bags to toys to plastic bottles. Due to its flexibility and thickness, we commonly use polyethylene as the raw material for plastic bags. Based on its molecular structure, polyethylene can be divided into several categories, each of which exhibits characteristics that make it unique. The most common types of polyethylene are High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE).

1. What’s HDPE

HDPE is an economical thermoplastic polymer with a straight-chain structure, manufactured at temperatures from 70ºC to 300ºC and pressures from 10 to 80 bar.

Due to the branched structure of the polymer chain, HDPE is much denser than LDPE. As a result, HDPE is more durable and tear-resistant but less flexible than LDPE. Products made from HDPE include rigid packaging containers, toys, outdoor furniture, kitchen plumbing, and more.

2. What is LDPE

LDPE is manufactured in a process called “radical polymerization,” which is a chain-growth polymerization in which successive additions of unsaturated monomer molecules form the polymer to a center of reactive radicals.

LDPE is flexible, chemically resistant and water-resistant. It is used to manufacture a variety of products, including food bags, cling film and film, and flexible packaging materials. It has lower density, strength and temperature resistance than HDPE plastic.

LDPE is no less valuable than HDPE. It is less dense because of the increased space between the few branches formed during the polymerization process, which makes it very flexible. LDPE also has better transparency, so it can be used as a bag where people can clearly see what is inside. And LDPE tears easily, which becomes an advantage when used as a bag for packaging items.

3. Similarities

LDPE and HDPE are essentially composed of the same polymerized ethylene molecules and therefore have many common characteristics. For example:

Both LDPE and HDPE materials are light in weight, both have some impact resistance, chemical resistance, water resistance, and more importantly, they both have low weaving costs.

These similar properties of LDPE and HDPE allow them to be used in a number of industries at the same time, such as packaging, piping, electrical, etc.

4. Differences

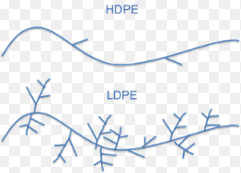

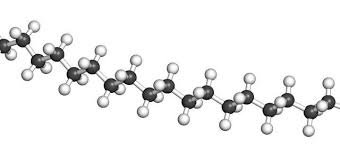

Both HDPE and LDPE are formed by the polymerization of polyethylene. The chemical process of polyethylene polymerization leads to the joining of monomers into long-chain hydrocarbons. As these chains form, the chains branch off in other directions. The pattern of branching determines the strength and density of the material.

More branches form a denser material, such as HDPE.

Fewer branches are the less dense LDPE.

Simply put, HDPE and LDPE have different densities, so HDPE is better suited for high-strength applications, while LDPE is better suited for applications requiring flexibility.

- Recyclability

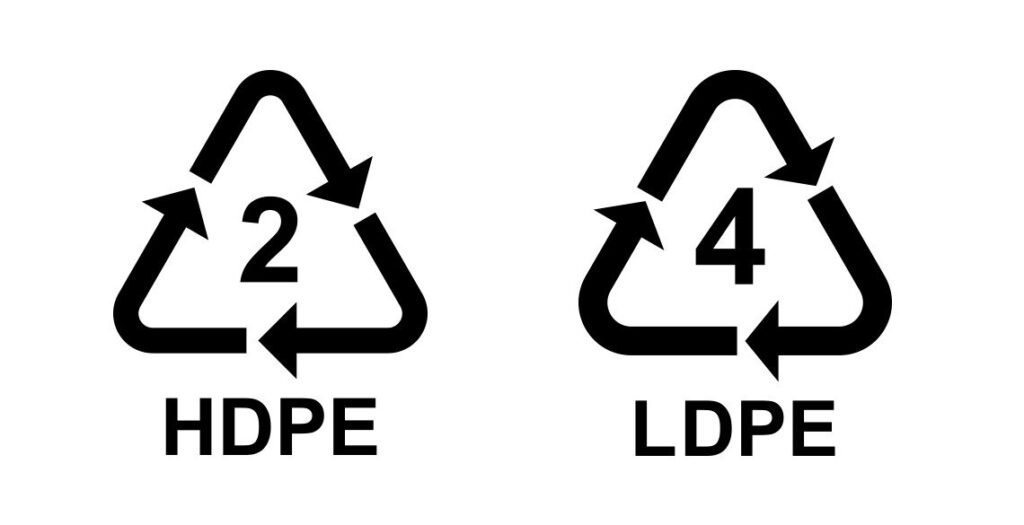

Both materials are recyclable; however, they have different recycling categories. LDPE is classified as a #4 recyclable, while HDPE is classified as a #2 recyclable. Depending on the properties of the product, LDPE is more difficult to recycle because it is softer and may not pass through recycling equipment as easily, while HDPE is easier to transport through recycling equipment.

- Physical properties

As mentioned earlier, LDPE is softer and more flexible than HDPE. It has a lower melting point, reaching 115°C to melt, and is more transparent. It is more prone to cracking under pressure than HDPE.

HDPE is strong and durable and has higher chemical resistance. The melting point is somewhat higher than LDPE, reaching 135°C, so it can withstand higher temperatures than LDPE. The more crystalline structure also results in a stronger and more opaque material.

5. Uses of HDPE/LDPE Poly Bags

HDPE plastic bags are suitable for placing irregular shapes, heavyweights, and sharp objects. For example construction materials such as cement or sand, bulk dry goods such as rice or grains and auto parts.

LDPE plastic bags are suitable for items that need to be lighter and have transparent properties that allow the items to appeal directly to customers. The most common ones are food, grocery packaging, etc.

6. Which is the best packaging for your product?

Now that you know the differences and advantages between HDPE and LDPE, do you know which material is more suitable for your needs, if it is still not very clear, then please consider the following questions: what do you need plastic bags for? Need to place the size of the product? Need the thickness of the plastic bag? How long do you need to reuse it? Do you need to support brand customization? How to dispose of waste plastic bags?

Give us the answers to these questions, then Airscape Textile will develop the ideal type for you. Please contact us if you have any needs.