1. Basic knowledge about PVC

PVC is made by reacting chlorine, carbon and ethylene together to form a compound called vinyl chloride monomer, or VCM. The VCM then undergoes a process called polymerization to produce base PVC(polyvinyl chloride), which looks like a white powder. Converting base PVC to textiles requires the addition of plasticizers, which are usually clear, oily liquids that help make plastics soft enough to be used in textiles such as clothing and backpacks.

Quite simply, PVC is a petrochemical product that is heavily processed from start to finish and can take many forms.

PVC fabrics are valued in these types of demanding applications because of their relatively high strength, durability, flexibility, and resistance to wear and tear. PVC fabrics are also favored by many manufacturers for their ease of use and long service life for versatility.

They require less energy to produce than most other types of industrial fabrics. Manufacturers are able to produce quality products at a lower cost.

PVC has an amorphous structure and contains halogens such as chlorine and fluorine, which are known for their stability. This chemical stability makes PVC excellent at resisting flames, chemicals, oils, etc.

2. How is PVC fabric’s quality?

PVC fabrics are widely used because of their many physical properties, while their chemical stability makes them very cost-effective for industrial applications.

With an ignition temperature of up to 455 degrees and insoluble in most organic solvents, such as oils and chemicals, PVC has a strong outer surface that can be processed and molded to create many fashionable items.

PVC textiles are extremely durable due to the molecular structure of PVC that combines chlorine atoms with all other carbon chains. Formally due to its resistance to oxidation, it is able to maintain good properties over long periods of time.

3. The benefits of PVC bag

3.1 Fashion

PVC bags can offer a lot of creative looks and can be designed to be very flexible as the shape and size can be changed according to the needs of the customer. The bags are lightweight but do not compromise on quality or length of use. PVC bags can be made into different shiny colors according to customers’ needs, and they can be your fashion accessories.

3.2 Protect items in it

PVC, unlike other plastic bags, does not contain toxic substances and the use of PVC bags does not harm the health of people. In addition, because PVC is very strong and durable, it protects the items in the bags from damage due to external crushing.

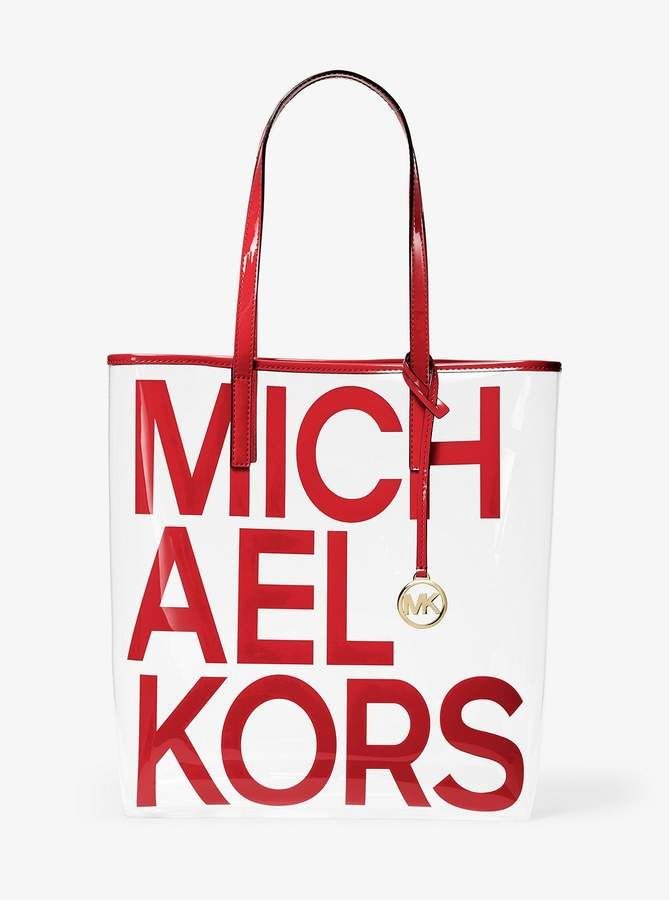

3.3 Customization

PVC bags are available in a variety of colors, allowing to follow the color scheme of the customer’s merchandise. They can also be printed with floral patterns, and add images and text or logos that can attract customers. Many companies have their branding information printed on the outside of the PVC bags. This can help you promote your brand and thus increase your sales.

3.4 Repeat use

Nowadays, people are fond of reusable items and are starting to switch to reusable items as the earth’s natural resources are depleting. PVC bags can save many natural resources and they are not only used for packaging retail items but also for keeping items in them for everyday use.

Every company wants low investment and high returns. Pvc raw materials are friendly in price and can also be manufactured according to your requirements. In addition, if you buy in bulk, you can reduce costs even more. Pvc bags will not cost you much budget but can help your business.

4. Conclusion

PVC bags are budget-friendly and can ease the burden on your budget. Their malleability and lightness in turn give people a convenient option for everyday travel. Reusable PVC bags protect the environment and reduce the use and discard of plastic bags. And the colorful colors are favored by the fashion crowd. The personalized design increases its audience range.