When it comes to bag products, 600D polyester is a kind of commonly used fabric. Many promotional bags adopt this fabric because of its sturdiness and reasonable price. As a bag purchaser, you sometimes may find it difficult to decide which bag material is the most suitable one, under these circumstances, 600D polyester may be your best choice, let’s find out why.

1. Do you know what you are buying?

1.1What is Denier

600D, where “D” stands for denier. Denier is one of the units of measurement for yarn thickness and is part of the direct yarn count system.

Denier is very important in the manufacture of fabrics because it directly affects thickness, sturdiness and durability. Therefore, fabrics with a higher denier count are more durable, while fabrics with a lower denier count tend to be soft and silky.

The higher the number in front of the “D”, the higher the thickness of the fabric, and the lower the number, the lower the thickness of the fabric.

1.2 Different 600D Grade

600D polyester is now the ‘basic’ fabric offered by almost all manufacturers. The 600D itself also contains many different grades. So, you may sometimes find that you have asked suppliers to quote in 600D, but the price quoted between them can vary considerably.

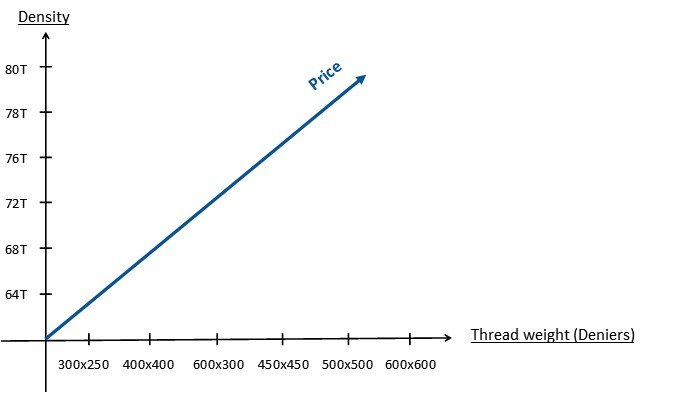

You may find it weird that your 600D seldom weaves with 600D thread. Commonly, 600D fabric is weaved with 300D*250D, 400D*400D, 600D*300D, 450D*450D or 500D*500D thread weights. Besides thread variation, there’s another factor that influences 600D fabric price, which is weaving density. There’re 6 density degrees, which are 64T, 68T, 72T, 76T, 78T, 80T. If you use the same thread, you will obviously buy the 64T dense fabric, because it is cheaper than the 80T and requires less thread and weaves faster.

1.3 Which 600D grade suits you?

There’re 3 major factors to consider when answering this question: Your target price, of course.

Performance of the material you need, such as tearing, tensile strength, and abrasion resistance.

Outlook of the product, that is, what kind of coating you need, PU or PVC coating. The PU coating is very thin and holds the woven threads together and seals the finished fabric. The PVC coating is thicker, which is twice the weight of the same fabric as a PU coating. The PVC coating is, of course, more expensive than PU. We generally recommend our customers to use 600D/PVC coating for solid color backpacks and 600D/PU fabric for large patterned backpacks.

For example, if you want to buy some heavy backpacks, such as tool kits, hiking bags, etc., denser materials and heavier threads will ensure the longevity and quality of the backpack.

2. Pros and Cons of 600D

2.1 Pros

The advantage of 600D polyester is very obvious: relatively inexpensive but very durable. The backpack needs to be flexible, so the fabric is not the thicker, the better. Cheap price doesn’t mean low quality, it’s often used to produce top-quality backpacks, such as Jansport.

2.2 Cons

Compared to cotton fabrics and other natural fibers, polyester does not breathe very well. Nowadays, depending on customer demand, some fabric manufacturers will blend polyester with other fibers to improve breathability.

3. The performance of 600D Polyester

3.1 The Strength

600D is strong enough to make backpacks or school bags for everyday use. However, it may not be the perfect fabric for someone expecting a super-durable military-grade backpack.

In addition, the backing material also has a significant impact on the strength of the fabric in use – 600D with a PVC backing is approximately 2.4 times stronger than a PU backing.

3.2 Abrasion Resistance

Abrasion testing is a way of simulating the performance of fabric under normal conditions of use.

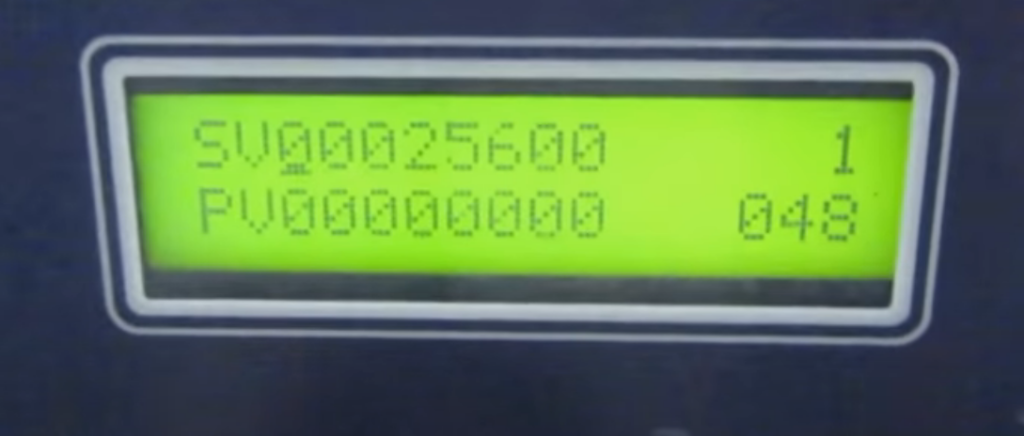

The abrasion resistance test method we have used this time is the Martindale method (SATRA TM31-2003), with a 12 kPa load, tested dry and under 25,600 cycles.

600D Polyester: Moderate abrasion after 25,600 cycles.

This is a very good result. After 25,600 cycles, which is a lot, the 600D polyester has held up well. It is fair to say that a backpack made of 600D polyester should last for years under normal and fair use.

3.3 Waterproof

600D can become waterproof after the process of PU coating.

4. How to ask your supplier about the quality of 600D?

If you don’t know the fabric, how do you ask your supplier about the quality of the fabric? The easiest way is to ask them about the characteristics of the fabric you have chosen. These characteristics relate to the denier of the thread, the density of the weave, the coating and whether it is waterproof.

You can refer to the following formula, fill in all the values and you will have an answer in your mind

“Composition, ……D x ……D, x ……T / backing — Surface finish”

Example: “Polyester 500D x 500D x 64T / PU – water-resistant treatment”

Two important pieces of information to assess the quality of 600D in the above formula are:

thread weight (denier) used in the warp and weft (…D x …D)

Weave density(…T)

The formula determines the price of your fabric.

5. Conclusion

Overall, 600 denier polyester, is a classic fabric used in the production of many everyday backpacks. It is a very durable material with good stability and high quality.

As mentioned earlier in the article, it is excellent value for money, as it is cheaper compared to products such as nylon and Cordura, but not worse in quality.