I. Introduction

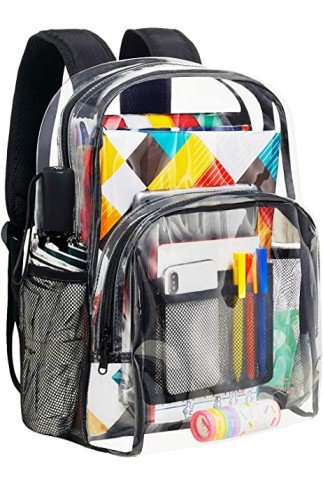

The purpose of this guide is to help sourcers and buyers of clear backpacks navigate the complex landscape of material quality issues in production. By providing an overview of common material quality issues, the causes behind them, and strategies for preventing them, this guide aims to empower sourcers to make informed decisions when sourcing clear backpacks from Chinese suppliers. Through the implementation of best practices and quality control measures, sourcers can mitigate the risks of material quality issues, ensuring that the clear backpacks they source meet safety regulations, quality standards, and end-user expectations.

II. Common Material Quality Issues in Clear Backpack Production

Clear backpacks can be prone to various material quality issues, such as flimsy vinyl that may tear or puncture easily if it is too thin. Similarly, weak stitching can result in seams that come apart over time, leading to a loss of shape and structure. Faulty zippers can also be a problem, as they may jam, break, or come off the tracks. The discoloration is another issue, as exposure to sunlight or other environmental factors can cause the backpack to become cloudy or opaque, thereby reducing its usefulness. In addition to these issues, some manufacturers may use toxic materials in the production of clear backpacks, such as lead, phthalates, and other harmful chemicals, which can pose health risks to users. Lastly, poor fitting can result in discomfort, pain, or injury to the user’s shoulders, back, or hips.

III. Causes of Material Quality Issues

The root causes of material quality issues in clear backpacks

One primary contributing factor is the use of low-quality materials by manufacturers, which may be motivated by cost-cutting measures. For example, opting for thin or brittle vinyl instead of higher-quality alternatives can result in backpacks that are prone to tearing or cracking under normal use conditions. This compromise in material quality directly affects the overall durability and functionality of the backpacks.

In addition, insufficient attention to manufacturing processes can lead to material quality issues. Inaccurate cutting or imprecise stitching during production can create weak spots in the backpacks, making them more susceptible to structural failures or seam separations over time. These manufacturing shortcomings compromise the overall strength and integrity of the backpacks, negatively impacting their performance and longevity.

Furthermore, the absence of robust quality control measures exacerbates material quality issues. Failure to inspect finished products for defects or to monitor the manufacturing process for errors can result in inconsistencies in the quality of the backpacks. This lack of quality control leads to variations in product integrity and reliability, making it challenging to ensure that each backpack meets the necessary safety regulations and quality standards.

Recognizing these root causes is crucial in addressing and preventing material quality issues. By prioritizing the use of high-quality materials, implementing precise manufacturing processes, and establishing rigorous quality control measures, manufacturers can enhance the overall quality and reliability of clear backpacks.

How these causes can be addressed

To address or avoid material quality issues in clear backpack production, several strategies can be employed.

- First, buyers can select high-quality materials that are durable and resistant to wear and tear. This will ensure that the backpacks have a longer lifespan and can withstand the rigors of regular use.

- Second, implementing rigorous manufacturing processes that include precise cutting, accurate stitching, and quality control measures can help avoid material quality issues. This will help ensure that the backpacks are produced to a consistent and high standard.

- Third, buyers can work closely with suppliers and quality assurance teams to establish and enforce clear quality standards. By monitoring and assessing the manufacturing process, suppliers and buyers can identify and address issues early on, preventing larger quality problems from arising later.

- Finally, buyers can play a role in ensuring material quality by working with trusted suppliers who prioritize quality, conducting regular inspections of finished products, and providing feedback to suppliers to improve their manufacturing processes.

IV. Best Practices for Working with Chinese Suppliers on Material Quality

To secure the production of high-quality clear backpacks from Chinese suppliers, effective communication of quality expectations and requirements is paramount. Achieving this involves best practices that include:

- Detailed and specific specifications: Furnishing the suppliers with explicit and comprehensive specifications on the materials, dimensions, and backpacks’ performance helps eliminate any misinterpretation and ensures that they grasp the necessary quality requirements.

- Sample approval process: Establishing a well-defined process for sample approval is crucial in conveying the quality expectations to the suppliers, enabling them to deliver the desired product.

- Regular communication: Maintaining frequent communication with the suppliers during the production process allows for prompt resolution of issues and ensures compliance with the necessary quality standards.

- Quality control protocols: Communicating clear and precise quality control protocols, which may include inspections and testing, can help ensure that the suppliers comprehend the required standards and enforce them.

- Training and education: Providing suppliers with relevant training and education on quality control standards and expectations can help them understand the quality requirements and equip them to produce a high-quality product.

V. Call to action

To avoid common material quality issues in clear backpack production, sourcers need to take proactive steps. This includes working with reputable suppliers who use high-quality materials and manufacturing processes, implementing quality control measures such as product testing and on-site inspections, and clearly communicating quality expectations and requirements to Chinese suppliers.

As a sourcer, it is your responsibility to ensure that the clear backpacks you source meet high-quality standards. By taking proactive steps to address material quality issues, you can ensure that your customers receive clear backpacks that are durable, functional, and meet their expectations.

Don’t wait until material quality issues arise. Take action now to prevent these issues from occurring and to build a reputation as a trusted supplier of high-quality clear backpacks.

VI. Conclusion

In conclusion, clear backpacks are gaining popularity due to their practicality and safety features. However, it’s crucial for sourcers to be aware of potential material quality issues that may arise during production. By understanding common issues and being proactive in addressing them, sourcers can ensure they source high-quality clear backpacks that meet customer expectations.

If you are interested in importing clear backpacks, we invite you to fill out the form on the right side to get in touch with us. Our experienced team is ready to assist you with any questions you may have and help you find the perfect clear backpack for your needs.