For larger purchases related to lunch bags, some of the critical variables that B2B buyers have to keep in mind in selecting the best material available in the market include cost, durability, insulation capability, environmental impact, and specific requirements of the target market. So, read our comprehensive guide to know what buyers need to look for in cooler box material to make the right decisions while considering business aspects.

1. Cost Efficiency

- Material Costs: All materials are not of the same cost. For example, basic polyester is probably cheaper than high-end nylon, or specialist insulation materials such as closed-cell foam.

- Bulk Purchase: Bulk purchase will enable the negotiation of discounts.

- Life Cycle Costs: Calculating the cost of ownership; there may be savings through lower replacement rates due to increased durability.

This material should be selected based on an all-encompassing cost-benefit analysis, including initial costs, potential bulk discounts, and durability in the long term.

2. Durability and Longevity

- Material Strength: Durable materials such as high-denier nylon and reinforced polyester will ensure that the cooler bags last a very long time without succumbing to rough handling or use.

- Wear and Tear: Check how well a material is rated regarding its abrasion resistance, puncture strength, and UV damage—prevalent in outdoor and transport use cases.

- Maintenance Needs: The materials that are easy to clean and maintain, for example, some coated fabrics, will add durability to the life span of cooler bags.

Select materials known for their strength and low maintenance requirements, thereby reducing the need for frequent replacements.

3. Insulation Properties

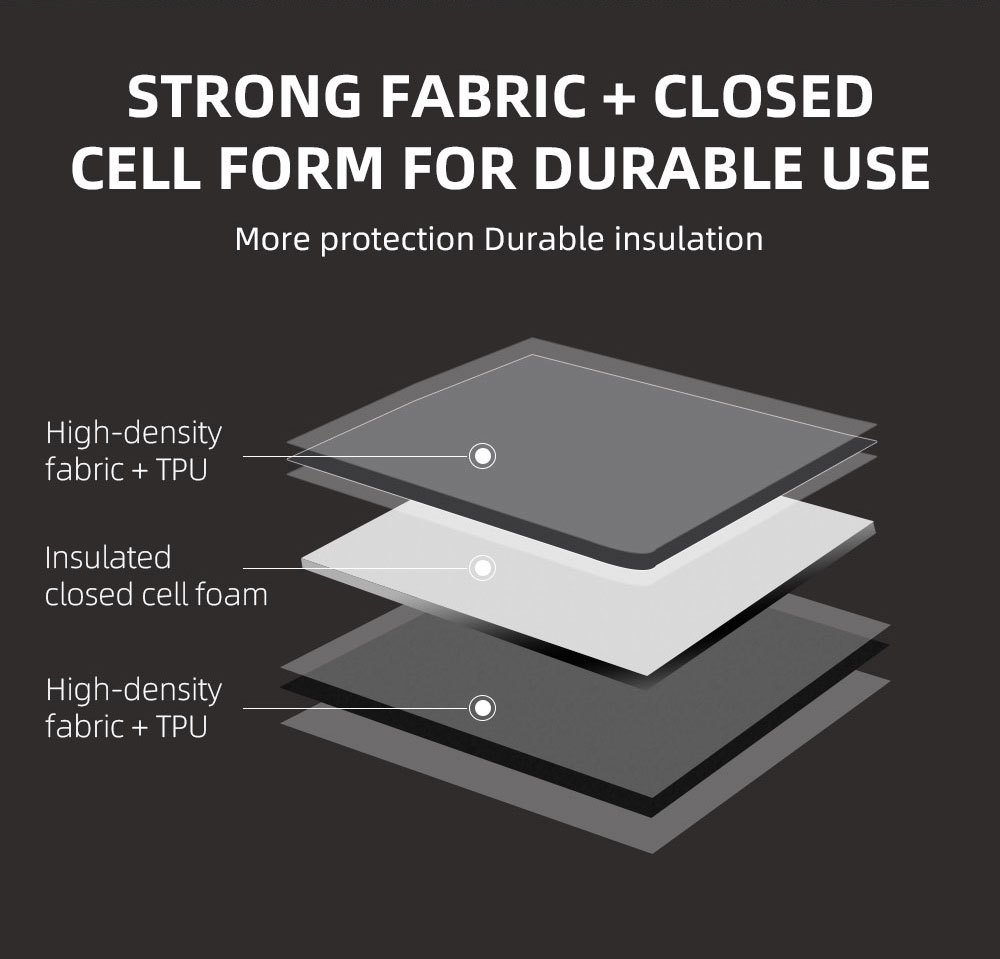

- Thermal Performance: Insulation materials such as closed-cell foam, PEVA (polyethylene vinyl acetate), and polyurethane foam effectively retain the required temperature within the cooler bags.

- Thickness and Density: In insulation, the quality usually increases with thickness and density. The capacity for thermal performance increases with thicker and denser insulating materials.

- Sealing Mechanisms: Ensure your cooler bags have a practical airtight zipper and robust seam, preventing temperature loss.

Go for materials with better insulation properties, ensuring a cooler bag that maintains the temperature of the contents for a long time— something crucial for food and beverage or pharmaceutical industries during transportation.

4. Environmental Impact

- Recyclability: Materials such as HDPE and some recyclable plastics have a lower environmental footprint.

- Sustainability Practices: Evaluate the overall ecological impact of a material, which covers its manufacturing process and disposal.

- Commodity chemical safety and recyclability regulations: The materials must meet the relevant rules for both chemical safety regarding the environment and their recyclability.

Select only sustainable materials and vendors practicing sustainable methods to help uphold and complement corporate social responsibility goals and attract environmentally aware customers.

5. Specific Market Requirements

- Target Market Needs: Understand what your target market will likely need. For example, pharmaceuticals will require cooler bags with a much more stable and reliable temperature control than those in the food delivery business, which could be looking for lightweight and easy-to-clean cooler bags.

- Regulatory Compliance: Industry-specific regulations and standards, such as FDA compliance for materials that should be safe for food.

- Customization Options: Some materials might allow for easy branding and customization, which can be necessary for promotional purposes or corporate identity.

Tailor the selection of the materials to meet the specific demands of the target market and compliance with industry standards to ensure high customer satisfaction and trust.

6. Common Cooler Bag Materials

6.1 Polyester

Pros:

- Inexpensive: Generally cheap, making it a favorite for budget customers.

- Lightweight: Lightweight and easy to carry and transport.

- Versatility: Comes in multiple designs and colors which can cater to different tastes and preferences.

Cons:

- Not that durable: It is less durable than reinforced or nylon fabrics and might get worn or torn easily.

- Insulation: Additional layers will be needed for good thermal performance.

Ideal For: Those looking for a cheaper customizing option for low-demand applications.

6.2 Nylon

Pros:

- Durability: High strength-to-weight ratio and will resist abrasions and punctures.

- Insulation: Works well with good insulation layers for the best thermal performance.

- Maintenance: Easy to clean and take care of.

Cons:

- Cost: It’s a bit costly compared to polyester, but worth it since this comes with more weight.

- Weight: A bit heavyweight compared to polyester; in this case, however, the cons outweigh the pros.

Ideal For: Buyers looking for long-lasting, high-performance cooler bags in robust environments like outdoor outings and frequent travels.

6.3 Polyethylene Vinyl Acetate (PEVA) and Polyurethane Foam

Pros:

- Insulation: Excellent thermal qualities, critical in retaining temperatures of contents sensitive to temperature.

- Flexibility: Light and easy to bend, making it possible to use in different bag designs.

- Non-toxic: Food-contact-safe alternative to chlorine-vinyl material.

Cons:

- Durability: This may require reinforcement when used in rigorous applications.

- Cost: A bit costly, given superior insulation attributes.

Ideal For: Industries that demand reliability in maintaining temperature, such as food transport services and pharmaceuticals.

6.4 High-Density Polyethylene (HDPE)

Pros:

- Durability: Extremely durable and resistant to impacts and chemicals.

- Recyclability: Eco-friendly as it is fully recyclable.

- Insulation: Often used in conjunction with foam layers to enhance insulation.

Cons:

- Weight: It is heavier than a fabric but delivers better durability.

- Flexibility: Less flexible, making it more suitable for rigid cooler box designs rather than soft-sided cooler bags.

Ideal For: Coolers that need robust, long-lasting solutions, such as industrial and heavy-duty transport.

7. Conclusion

Selecting the appropriate cooler bag material for bulk purchases involves several key factors, including cost efficiency, durability, insulation properties, and environmental impact. By understanding the specific needs of your industry and target market, you can make informed decisions that not only meet performance requirements but also align with sustainability goals and regulatory standards. Investing in the right materials enhances the value of cooler bags, ensuring they provide reliable service and satisfaction to end-users.

Why Choose Our Cooler Bags

Our company offers a premium selection of cooler bags designed with high-quality materials to meet the demanding needs of B2B buyers. Our cooler bags feature:

- Superior Insulation: Utilizing advanced closed-cell foam and PEVA linings, our cooler bags maintain optimal temperatures for extended periods.

- Durable Construction: Made from high-denier nylon and reinforced polyester, our bags are built to withstand harsh conditions and frequent use.

- Customizable Options: We offer a variety of customization options to showcase your brand, including logo printing and tailored designs.

- Eco-Friendly Materials: Committed to sustainability, our cooler bags are made with recyclable materials and eco-conscious manufacturing processes.

Partner with us to ensure your bulk purchase of cooler bags delivers on quality, performance, and environmental responsibility. Contact us today to learn more about our product offerings and how we can meet your business needs.