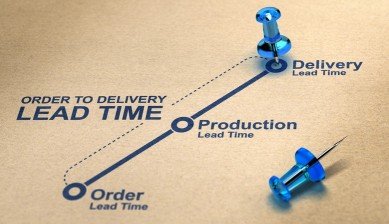

Lead times represent the duration between the initiation of a process, like placing an order, and its completion, such as receiving the finished product. In the realm of manufacturing and supply chains, understanding lead times is paramount. It ensures timely product delivery, essential for maintaining customer satisfaction. Furthermore, accurate lead time knowledge aids in efficient inventory management, preventing overstocking costs or understocking pitfalls, and assists businesses in managing cash flows by reducing tied-up capital in unsold inventory. Hence, lead times hold significant operational, financial, and reputational implications for businesses.

1. Factors Contributing to Lead Times

Several variables can impact the length of lead times in manufacturing. Some of the key factors include:

- Design Complexity: A product with intricate designs or features typically requires more time to produce. The need for specialized machinery, additional labor, or unique materials can prolong the production process.

- Material Availability: The accessibility of required raw materials plays a critical role. If materials are scarce or need to be imported, this can add significant time to the lead.

- Production Capacity: A manufacturer’s operational efficiency and capacity directly influence lead times. Facilities with outdated machinery or limited workforce might face longer production times.

- Quality Control Processes: Rigorous quality checks ensure the product meets standards but can also extend lead times. The depth and extent of these checks vary based on product type and industry regulations.

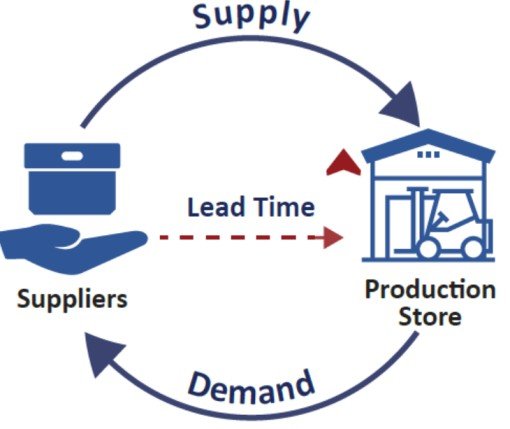

- Supplier Reliability: If a manufacturer relies on third-party suppliers for components or materials, the reliability of these suppliers becomes crucial. Delays from suppliers inevitably extend the manufacturer’s lead times.

- Volume of Order: Larger orders might take longer to fulfill, especially if the manufacturer’s capacity is already near its limit or if there are multiple large orders in the queue.

- External Factors: Unforeseen circumstances like natural disasters, geopolitical events, or transportation disruptions can also affect lead times. Manufacturers with solid contingency plans may better navigate these challenges.

2. The Importance of Lead Times in Bag Manufacturing

Meeting Market Demand: Ensuring Timely Delivery to Customers

Lead times directly influence a manufacturer’s ability to satisfy market demand. For bag manufacturers, where fashion trends can shift rapidly, being able to produce and deliver promptly is critical. A short and consistent lead time ensures that retailers and end-users receive their orders when expected, fostering trust and loyalty.

Seasonal Trends and Timely Product Launches

Bags, like many fashion items, often follow seasonal trends. Whether it’s beach totes for summer or leather satchels for autumn, timing is everything. A prolonged lead time can result in missing the peak sales window, leaving manufacturers with outdated stock. On the contrary, optimized lead times enable manufacturers to launch products just when the market is ripe, maximizing sales potential.

Inventory Management: Avoiding Overstock or Stockouts

Efficient lead time management aids bag manufacturers in streamlining their inventory. By accurately predicting production times, they can avoid excessive stock accumulation, which ties up capital and storage space. Simultaneously, they can prevent stockouts, which could lead to missed sales and disgruntled customers. An efficient inventory bolstered by optimal lead times can thus strike a balance, minimizing costs while ensuring availability.

Managing Cash Flow and Financial Forecasts

Cash flow is the lifeblood of any business, and for bag manufacturers, tied-up capital in unsold stock can strain financial resources. By managing and optimizing lead times, manufacturers can better predict their cash inflow from sales and outflow for production costs. This enhanced visibility aids in accurate financial forecasting, helping businesses make informed decisions about investments, expansions, and other financial commitments.

3. Impacts of Poor Lead Time Management

Potential Loss of Customers or Clients In a fast-paced market, customers and clients have high expectations for timely deliveries. If a manufacturer consistently fails to meet promised lead times, it risks losing clients to competitors who can deliver more reliably. Over time, repeated delays can erode customer trust, resulting in diminished loyalty and fewer repeat orders.

Increased Warehousing Costs Due to Holding Excessive Inventory Poor lead time management can often lead to overproduction, resulting in excessive inventory. This surplus not only ties up capital but also incurs additional warehousing costs. Larger storage spaces, increased utility bills, and higher personnel costs to manage the inventory are just a few of the added expenditures businesses may face.

Disruptions in Supply Chain, Leading to Production Halts Inaccurate lead time predictions can cascade through the supply chain. For instance, if materials are ordered based on flawed lead time estimates, it can lead to shortages or overstock of critical components. Such mismatches can disrupt the production process, causing halts or inefficiencies, which further compound lead time issues.

Negative Effects on Brand Reputation Consistent failures in meeting lead times can have long-term consequences on a brand’s image. In the age of social media and online reviews, word of negative experiences spreads quickly. Poor lead time management can lead to public complaints, which can deter potential customers and harm the brand’s standing in the marketplace.

4. Advantages of Optimal Lead Times

Just-In-Time (JIT) Production and Inventory Management Optimal lead times pave the way for Just-In-Time (JIT) manufacturing, a strategy that aims to improve a business’s ROI by reducing in-process inventory and its associated costs. By producing goods only as they’re needed for the next phase of customer sale, manufacturers can significantly cut down on storage costs and minimize the risks associated with holding obsolete inventory.

Enhancing Customer Satisfaction and Trust When manufacturers consistently meet or exceed their promised delivery times, it naturally bolsters customer satisfaction. Timely deliveries signal reliability, and over time, this reliability fosters trust. A reputation for trustworthiness can serve as a unique selling point, differentiating a brand in a crowded market and encouraging repeat business.

Efficient Utilization of Resources, Reducing Wastage Optimal lead times ensure that resources, whether they be raw materials, machinery, or labor, are used efficiently. By aligning production schedules with actual demand, manufacturers can minimize idle times and reduce resource wastage. This efficiency not only brings down costs but also promotes sustainable and environmentally friendly practices.

Greater Flexibility in Responding to Market Changes Markets are dynamic, and consumer preferences can shift rapidly. Manufacturers with optimal lead times are better positioned to adapt to these changes. Whether it’s a sudden surge in demand or an unforeseen supply chain disruption, shorter and well-managed lead times allow for quicker adjustments, ensuring that the business remains resilient and agile in the face of change.

5. Key Considerations When Evaluating OEM Bag Manufacturers

Transparency: OEM’s Openness About Their Lead Time Components When partnering with an OEM bag manufacturer, it’s essential to gauge their transparency regarding lead times. A trustworthy manufacturer will be candid about all components of their lead time, from material sourcing to production processes and final dispatch. This openness provides businesses with a clear picture of where potential delays might arise and how they can be addressed.

Track Record: Past Performance in Meeting Lead Times Historical data can provide a reliable indicator of an OEM’s efficiency. Prospective partners should investigate how consistently the manufacturer has met its lead time promises in the past. A consistent track record suggests a well-established production process and the manufacturer’s commitment to timely delivery.

Contingency Planning: How They Manage Unforeseen Delays or Disruptions No matter how streamlined a process may be, unexpected disruptions can and do occur. Whether it’s a supply chain hiccup, equipment malfunction, or external factors like natural disasters, an OEM’s ability to navigate these disruptions speaks volumes about their reliability. It’s crucial to understand their contingency plans, backup suppliers, and alternative production methods to maintain consistent lead times.

Communication: Regular Updates and Easy Accessibility for Queries Effective and open communication is the cornerstone of any successful partnership. When evaluating OEMs, it’s essential to note how readily they provide updates about production progress, potential delays, or changes in lead times. Moreover, their responsiveness to queries, concerns, or feedback can significantly impact the smoothness of the collaboration.

Reviews and Testimonials: Feedback from Other Businesses on Lead Time Adherence In today’s digital age, reviews and testimonials offer invaluable insights into an OEM’s operations. Businesses should seek out feedback from other clients or partners of the manufacturer. These testimonials can shed light on the OEM’s adherence to lead times, their communication practices, and overall reliability.

6. Tips for Businesses to Manage Lead Times Effectively

Collaborate Closely with Your Chosen OEM Open communication and collaboration are key to managing lead times. By establishing regular check-ins, sharing forecasts, and discussing potential market shifts, businesses can ensure that the OEM is well-prepared to adjust production schedules as needed. Such proactive communication can preempt many issues before they escalate.

Maintain a Buffer Stock for Emergencies While Just-In-Time (JIT) production can be efficient, having a safety buffer stock can be a lifesaver in unforeseen situations. Whether it’s a sudden surge in demand or a minor disruption in the supply chain, this buffer can help maintain regular operations and meet customer needs without a hitch.

Implement a Robust Forecasting System Accurate forecasting can significantly enhance lead time management. By predicting demand and market trends, businesses can provide their OEMs with a clearer picture of upcoming production needs. Modern tools, software, and data analytics can help refine these forecasts, aligning production more closely with market realities.

Regularly Review and Adjust Based on Historical Lead Time Performance Past performance can provide invaluable insights for future operations. By regularly reviewing historical lead time data, businesses can identify patterns, bottlenecks, and areas for improvement. These reviews can guide adjustments in processes, partnerships, or strategies to optimize lead times continually.

Diversify Suppliers When Feasible to Mitigate Risks Relying solely on one supplier or OEM can be a risky proposition. In the face of disruptions, having diversified suppliers ensures that production can continue unabated. Whether it’s sourcing raw materials from multiple vendors or partnering with multiple OEMs for different product lines, diversification can provide a safety net against unforeseen challenges.

7. Conclusion

As we’ve explored throughout this blog, effective management of these timelines can significantly impact a business’s operational efficiency, customer satisfaction, and bottom line. In an era where customer expectations are at an all-time high and market dynamics shift rapidly, the emphasis on optimizing lead times has never been more crucial. By fostering transparent collaborations, leveraging data-driven forecasting, and being adaptable in the face of unexpected challenges, businesses can not only meet but exceed market demands.

At Airscape, we understand the importance of efficient lead time management and are dedicated to providing timely solutions tailored to your unique needs. Our team of experts is on hand to offer insights, answer any queries, and ensure that your operations run seamlessly. Let’s collaborate to achieve optimal lead times, ensuring timely deliveries and maximizing operational efficiency. Your success is our priority. Reach out to us today by filling out the form on this page or just click here.