Backpacks are a popular and practical accessory used by people of all ages for various purposes. However, the production and disposal of traditional backpack materials can have a significant impact on the environment. Fortunately, there is a growing trend towards eco-friendly fabric alternatives that offer a sustainable and responsible choice for backpack manufacturing. In this article, we will explore some of the most promising eco-friendly fabrics that can be used to create backpacks. From recycled materials to innovative plant-based fibers, we will uncover sustainable options that prioritize both style and environmental consciousness.

1. Introduction

Backpacks have become an essential part of our daily lives, serving as reliable companions for work, travel, and outdoor adventures. However, the manufacturing process and the materials used to create backpacks can have detrimental effects on the environment. To address this concern, designers and manufacturers are increasingly turning to eco-friendly fabric alternatives. These materials offer a sustainable solution that minimizes environmental impact without compromising on style or functionality.

2. Traditional Backpack Materials and Their Environmental Impact

Traditional backpacks are typically made from materials like nylon, polyester, and synthetic fabrics. While these materials are durable and affordable, their production involves the extraction of non-renewable resources and the release of harmful chemicals into the environment. Additionally, the disposal of these backpacks often contributes to landfill waste and pollution.

3. Recycled Polyester: A Sustainable Solution

Recycled polyester, also known as rPET, is gaining popularity as an eco-friendly fabric alternative. It is made from post-consumer plastic bottles that are processed and spun into polyester yarns. By using recycled materials, this fabric helps reduce the demand for new petroleum-based resources and diverts plastic waste from landfills and oceans. Recycled polyester offers similar durability and performance to conventional polyester, making it an excellent choice for backpacks.

4. Hemp: A Versatile and Earth-Friendly Fabric

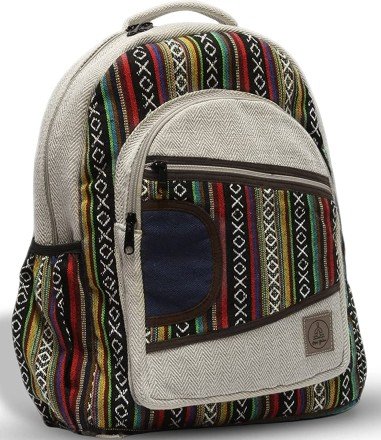

Hemp is a versatile plant that has been used for centuries to create textiles. It requires minimal water and pesticides to grow, making it a highly sustainable option. Hemp fabric is known for its durability, breathability, and resistance to mold and UV rays. It can be blended with other fibers or used on its own to create sturdy and eco-friendly backpacks.

5. Organic Cotton: Softness with Sustainability

Organic cotton is grown without the use of harmful pesticides, making it a safer and more environmentally friendly alternative to conventional cotton. It is softer and more breathable than synthetic fabrics, providing comfort while minimizing the ecological footprint. Organic cotton backpacks are an excellent choice for those seeking a natural and sustainable option.

6. Cork: A Unique and Renewable Material

Cork is a natural and renewable material that is harvested from the bark of cork oak trees. It is lightweight, water-resistant, and has excellent insulating properties. Cork fabric is produced by grinding the cork bark and then combining it with a textile backing. It offers a unique and stylish option for eco-conscious backpacks.

7. Piñatex: A Leather Alternative from Pineapple Leaves

Piñatex is a sustainable and cruelty-free alternative to traditional leather. It is made from pineapple leaf fibers, a byproduct of the pineapple industry. These fibers are transformed into a non-woven textile that resembles leather. Piñatex is not only eco-friendly but also provides additional income for pineapple farmers, making it a socially responsible choice.

8. Bamboo: A Fast-Growing and Renewable Resource

Bamboo is a fast-growing plant that requires minimal water and no pesticides to thrive. It can be processed into a soft and durable fabric that is naturally antibacterial and hypoallergenic. Bamboo fabric has excellent moisture-wicking properties, making it suitable for backpacks used in active and outdoor settings.

9. Blended Fabrics: Combining Sustainability and Durability

Blending eco-friendly fabrics with other materials can result in a combination that offers both sustainability and durability. For example, a backpack made from a blend of recycled polyester and hemp can provide the benefits of both materials while reducing their individual limitations. By combining different eco-friendly fabrics, manufacturers can create backpacks that are both eco-conscious and long-lasting.

10. Dyeing and Finishing: Eco-Friendly Approaches

In addition to choosing eco-friendly fabrics, the dyeing and finishing processes also play a crucial role in creating sustainable backpacks. Opting for low-impact dyes that minimize water usage and harmful chemicals can further reduce the environmental impact. Similarly, using water-based or natural finishes instead of toxic coatings ensures a more sustainable end product.

11. The Role of Certification in Identifying Sustainable Fabrics

Certifications such as Global Organic Textile Standard (GOTS) and Bluesign provide assurance that the fabrics used in backpacks meet specific environmental and social criteria. These certifications help consumers identify sustainable products and encourage manufacturers to prioritize eco-friendly practices. When choosing an eco-friendly backpack, look for these certifications as a sign of sustainability and responsible sourcing.

12. Benefits of Choosing Eco-Friendly Fabrics for Backpacks

By opting for backpacks made from eco-friendly fabrics, you can enjoy several benefits. Firstly, you contribute to the preservation of the environment by reducing waste, conserving resources, and minimizing pollution. Secondly, eco-friendly fabrics often offer superior breathability, durability, and comfort compared to synthetic materials. Finally, choosing sustainable backpacks helps support ethical and responsible manufacturing practices.

13. Conclusion

As awareness of environmental issues grows, the demand for eco-friendly backpacks is on the rise. By exploring alternative fabric options, manufacturers and consumers can make a positive impact on the planet while still enjoying functional and stylish backpacks. From recycled polyester to organic cotton, hemp to mushroom leather, there are numerous sustainable choices available. Embracing these eco-friendly fabric alternatives paves the way for a greener and more responsible backpack industry.

FAQs

1. Are backpacks made from eco-friendly fabrics as durable as those made from traditional materials?

Yes, eco-friendly fabrics can be just as durable as traditional materials. Many eco-friendly fabrics offer excellent durability and performance, making them suitable for backpacks that withstand everyday use and outdoor activities.

2. Can eco-friendly backpacks be waterproof?

Some eco-friendly fabrics, such as recycled polyester and cork, offer water-resistant properties. However, for full waterproofing, additional treatments or coatings may be required, which may impact the overall sustainability of the backpack.

3. How can I ensure that an eco-friendly backpack is genuinely sustainable?

Look for certifications such as GOTS and Bluesign, which guarantee that the backpack meets specific environmental and social criteria. Additionally, research the brand’s sustainability practices and materials sourcing to ensure their commitment to sustainability aligns with your values.

4. Are eco-friendly backpacks more expensive than traditional backpacks?

Eco-friendly backpacks can vary in price depending on factors such as the brand, design, and materials used. While some eco-friendly options may be more expensive, others may be comparable or even more affordable than traditional backpacks.

5. How can I properly dispose of an eco-friendly backpack at the end of its life?

To ensure minimal environmental impact, consider donating the backpack for reuse or recycling it through specialized programs or facilities. Some eco-friendly backpack materials, such as recycled polyester, can be further recycled into new products. Check with local recycling centers or contact the manufacturer for guidance on proper disposal methods.